Why ST Air, Pump & Power:

This is not a collection of components — it is an engineered air unload and power solution for liquid transport. Every part is selected and integrated to work together, delivering dependable unloading performance and long-term reliability.

System Overview:

The ST Air, Pump & Power package is a compact, fully integrated PTO-driven system engineered specifically for air unloading liquid trailers and powering trailer-mounted pumps or compressors. It provides controlled, reliable air supply and hydraulic power to support liquid transfer operations on tank trucks and liquid bulk trailers.

This package integrates air compression, hydraulic pumping, and PTO power into a single engineered assembly. The design simplifies installation, improves reliability, and provides excellent service access in demanding liquid-transfer applications.

Typical Applications:

- Liquid bulk trailers with air unload systems

- Fuel, lube oil, and chemical tank trucks

- Liquid transfer systems requiring controlled air pressure

- Multi-function vocational liquid transport vehicles

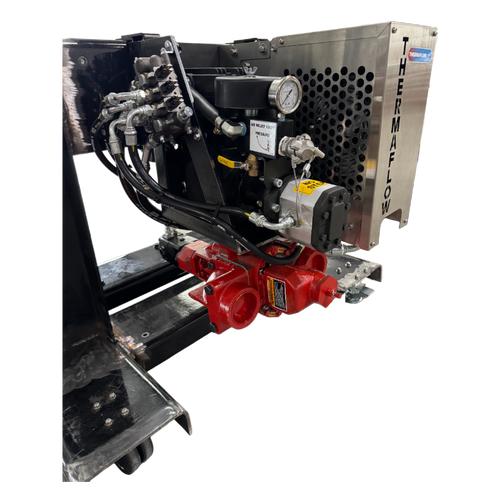

Key Components:

- Gardner Denver Air Compressor

- Roper Pump

- APSCO Hydraulic Cooler

- Selector Valve Assembly

Design Advantages:

- Compact, space-efficient footprint

- Integrated mounting and component alignment

- Clean, organized plumbing layout

- Improved service access

- Reduced installation time

- Designed specifically for liquid air unload systems

Pump & Air Specifications:

Pump Option - Roper 4622 Gear Pump:

| Maximum Flow Rate | 154 GPM* |

| Maximum Operating Temperature | 250°F |

| Maximum Differential Pressure | 125 PSI |

Air Compressor Option - Gardner Denver GD70 Air Compressor:

| Operating Pressure | 25 PSI (standard) / 36 PSI (high-pressure configuration) |

| Airflow | 29 CFM |

| Equivalent Liquid Unload Rate | 67 GPM** |

Hydraulic Cooler Option - Thermaflow 934 Hydraulic Cooler:

| Maximum Flow Rate (Cooling Capacity) | 30 GPM |

| Maximum Operating Pressure | Up to 3000 PSI |

* - Actual flow rates may vary based on product viscosity, temperature, and unloading conditions.

** - Equivalent liquid flow is application-dependent and based on typical air unload conditions.