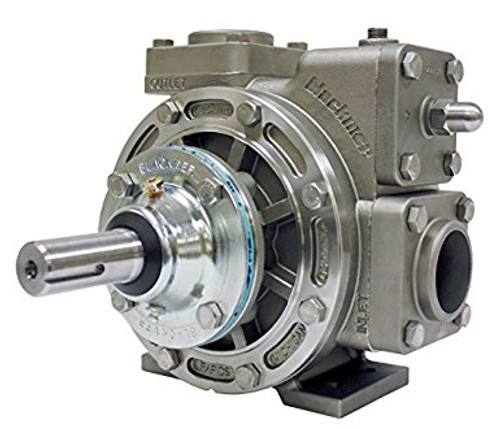

Blackmer® STX DEF Series Pumps, which are part of the Stainless Line of sliding vane pumps, meet or exceed all industry specifications for DEF Aqueous Urea Solutions (AUS32), also known as AdBlue®. Made from 316 stainless steel, the pumps are compatible with DEF and feature external ball bearings, non-metallic Duravanes, PTFE elastomers and Blackmer chemical mechanical seals. The design also includes an adjustable relief valve, weld flanges and self-priming capability. The STX3-DEF has a versatile mounting bracket.

STX3-DEF pumps offer fast fluid off-loading. For example, typical off-loading of a 6,000 gallon (22,700 liter) tanker can be unloaded as quickly as 24 minutes. The Blackmer non-metallic vanes self-compensate for wear and allow the STX DEF Series pumps to run dry for short periods of time for self-priming and blowing lines clean, without pump damage. The STX DEF Series is designed to offer easy maintenance because the internal wear is almost completely limited to the sliding vanes, which can be replaced with ordinary hand tools.

For applications that require smaller flow rates, the Blackmer SX1-DEF Series Pump constructed from 304 & 316 stainless steel, offers 2 to 10 gpm (8 - 38 L/min) values.

FEATURES:

- Meets or exceeds all industry specifications for DEF Aqueous Urea Solutions (AUS32)

- 316 stainless-steel pump with external ball bearing construction (SX1 model has 304 stainless steel for the cylinder and 316 stainless steel for the head).

- Blackmer chemical mechanical seals and non-metallic vanes for longer life with corrosive products

- Pump design and operation minimizes shear and agitation

- Adjustable relief valve protects pump against excessive pressures

- Advantages of sliding vane technology:

- Unique sliding-vane pump design self-adjusts for wear to maintain flow rates

- Excellent self-priming and dry-run capabilities

- Sliding vane design provides sustained performance and trouble-free operation

- Easy maintenance: vanes can be easily replaced without removing the pump

- High suction lift and line-stripping capabilities

- Low maintenance and low life-cycle costs